The circuit breaker in the instrument lighting system protects the electrical components from damage by interrupting the flow of electricity in the event of a fault. This is essential for preventing fires and other hazards.

Circuit breakers are designed to trip when the current flowing through them exceeds a certain level. This can happen if there is a short circuit or if too many devices are plugged into the same circuit. When a circuit breaker trips, it opens the circuit, stopping the flow of electricity.

Circuit Breaker Function

Circuit breakers in instrument lighting systems serve as protective devices, safeguarding the system against electrical faults and potential damage. Their primary function is to interrupt the flow of electrical current when it exceeds a predetermined safe level.

When an electrical fault occurs, such as a short circuit or overload, the circuit breaker’s internal mechanism trips, opening the circuit and disconnecting the faulty component. This action isolates the fault and prevents it from spreading to other parts of the lighting system, minimizing the risk of fire or equipment damage.

Circuit Breaker Characteristics

Circuit breakers used in instrument lighting systems typically possess specific characteristics and specifications to meet the system’s requirements. These include:

- Current Rating:The maximum amount of current the circuit breaker can handle before tripping.

- Tripping Time:The time it takes for the circuit breaker to trip after detecting an overcurrent condition.

- Voltage Rating:The maximum voltage the circuit breaker can withstand without breaking down.

- Resettable or Non-Resettable:Whether the circuit breaker can be manually reset after tripping or requires replacement.

- Type:There are various types of circuit breakers, such as thermal, magnetic, or electronic, each with its own operating principle.

Circuit Breaker Installation and Maintenance

Proper installation and maintenance are crucial for the optimal performance of circuit breakers in instrument lighting systems. Installation procedures typically involve:

- Selecting the appropriate circuit breaker based on system specifications.

- Correctly connecting the circuit breaker to the electrical wiring.

- Mounting the circuit breaker securely in the designated location.

Maintenance includes:

- Regular visual inspections for any signs of damage or wear.

- Periodic testing to ensure proper tripping and reset functionality.

- Cleaning and tightening connections to prevent corrosion or loose contacts.

Circuit Breaker Troubleshooting, The circuit breaker in the instrument lighting system protects the

Troubleshooting circuit breakers in instrument lighting systems involves identifying and resolving common problems. Some potential issues include:

- Tripped Circuit Breaker:This can be caused by an electrical fault, overload, or a faulty circuit breaker.

- Circuit Breaker Not Tripping:This can indicate a malfunctioning circuit breaker or a problem with the electrical wiring.

- Nuisance Tripping:Circuit breakers tripping frequently without an apparent fault can be caused by loose connections, improper wiring, or a defective circuit breaker.

Troubleshooting steps typically involve:

- Identifying the affected circuit and visually inspecting the circuit breaker.

- Checking the electrical wiring for any damage or loose connections.

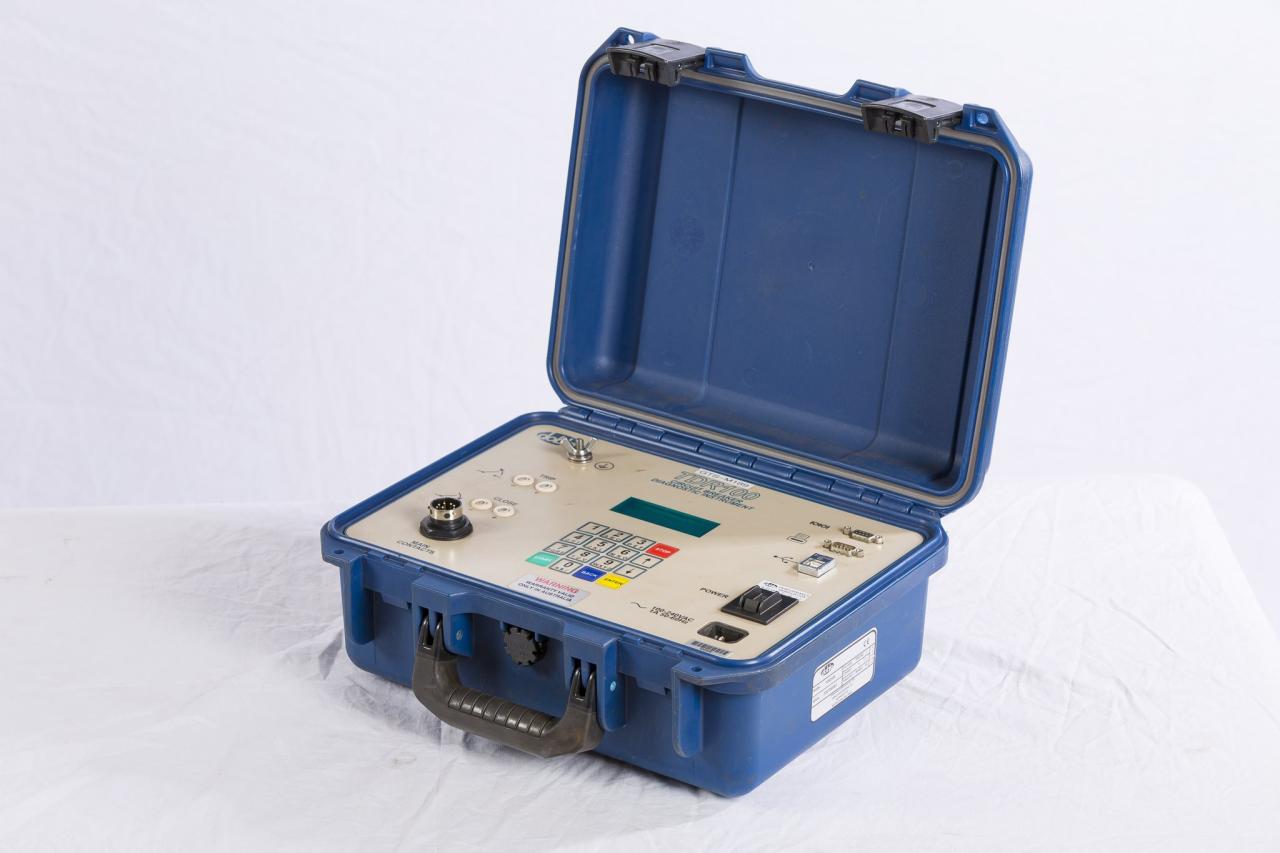

- Testing the circuit breaker’s functionality using appropriate equipment.

- Replacing the circuit breaker if it is found to be faulty.

Circuit Breaker Safety Considerations

When working with circuit breakers in instrument lighting systems, it is essential to adhere to safety precautions. These include:

- Always turn off the power supply before working on circuit breakers.

- Use insulated tools and wear appropriate personal protective equipment.

- Avoid touching live electrical components.

- Follow manufacturer’s instructions and safety guidelines.

Case Studies or Examples

In a commercial aircraft’s instrument panel lighting system, a circuit breaker prevented a potential electrical fire by tripping when a short circuit occurred. The quick response of the circuit breaker isolated the fault, preventing damage to other components and ensuring the safety of the flight crew and passengers.

In an industrial control system, a circuit breaker malfunction caused a power outage. Troubleshooting revealed a loose connection in the wiring, which was subsequently repaired. The circuit breaker’s proper operation prevented further damage and ensured the uninterrupted operation of the control system.

Commonly Asked Questions: The Circuit Breaker In The Instrument Lighting System Protects The

What is a circuit breaker?

A circuit breaker is a safety device that interrupts the flow of electricity in the event of a fault.

How does a circuit breaker work?

A circuit breaker works by tripping when the current flowing through it exceeds a certain level. This can happen if there is a short circuit or if too many devices are plugged into the same circuit.

What are the different types of circuit breakers?

There are two main types of circuit breakers: thermal circuit breakers and magnetic circuit breakers. Thermal circuit breakers trip when the current flowing through them exceeds a certain level for a period of time. Magnetic circuit breakers trip when the current flowing through them exceeds a certain level instantaneously.

Where are circuit breakers used?

Circuit breakers are used in a variety of applications, including homes, businesses, and industrial facilities.