Rigging equipment must be inspected by a competent person to ensure its safe operation and to prevent accidents. A competent person is someone who has the knowledge, skills, and experience to identify and assess the condition of rigging equipment and to make decisions about its continued use.

The scope of an inspection will vary depending on the type of equipment being inspected, but it should generally include a visual examination of all components, a check of the equipment’s operating mechanisms, and a test of the equipment’s load capacity.

Definition of Competent Person

A competent person is an individual who possesses the knowledge, skills, and experience to perform a specific task or duty safely and effectively. In the context of rigging equipment inspection, a competent person must have a thorough understanding of rigging equipment, its uses, and potential hazards.

They must also be familiar with applicable codes, standards, and regulations.

Qualifications and Responsibilities

- Has received specific training and/or experience in rigging equipment inspection.

- Is familiar with the equipment being inspected and its intended use.

- Is knowledgeable about the applicable codes, standards, and regulations governing rigging equipment inspection.

- Is able to identify and assess potential hazards associated with rigging equipment.

- Is able to make sound judgments and decisions regarding the safety and suitability of rigging equipment.

- Is able to effectively communicate inspection findings and recommendations.

Examples of Competent Persons, Rigging equipment must be inspected by a competent person

- Rigging inspectors certified by a recognized organization.

- Experienced engineers or technicians who have received specialized training in rigging equipment inspection.

- Individuals who have demonstrated a high level of knowledge and skill in rigging equipment inspection through their work experience.

Scope of Inspection

Rigging equipment inspection should cover all components of the equipment, including:

- Load-bearing members (e.g., hooks, shackles, chains, slings)

- Attachments and connections

- Hardware (e.g., bolts, nuts, pins)

- Safety devices (e.g., latches, locks)

The frequency of inspections should be based on the frequency of use, the severity of the application, and the environmental conditions. Inspections should be performed more frequently for equipment that is used frequently, subjected to heavy loads, or exposed to harsh conditions.

Inspection findings should be documented and maintained for future reference. The documentation should include the date of the inspection, the name of the inspector, the equipment inspected, the condition of the equipment, and any identified defects or damage.

Inspection Procedures: Rigging Equipment Must Be Inspected By A Competent Person

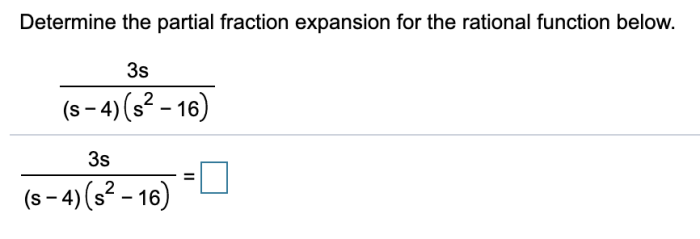

Rigging equipment inspections should be conducted in a systematic manner to ensure that all components are thoroughly inspected. The following steps should be included in a typical inspection procedure:

- Visual inspection:Examine the equipment for any visible defects, damage, or corrosion.

- Functional test:Test the equipment to ensure that it operates properly.

- Load test:Apply a load to the equipment to verify its strength and integrity.

- Non-destructive testing:Use non-destructive testing methods (e.g., magnetic particle inspection, ultrasonic testing) to detect hidden defects.

Inspectors should use specialized tools and equipment, such as magnifying glasses, torque wrenches, and load cells, to assist in the inspection process.

Reporting and Corrective Actions

Inspection findings should be documented in a written report. The report should include the following information:

- Date of the inspection

- Name of the inspector

- Equipment inspected

- Condition of the equipment

- Any identified defects or damage

- Recommendations for corrective actions

The inspection report should be reviewed by a qualified person to determine the appropriate corrective actions. Corrective actions may include repairs, replacements, or modifications to the equipment. Inspection records should be maintained for future reference.

Safety Considerations

Rigging equipment inspections are critical to ensuring the safety of personnel and equipment. Inspectors must be aware of the potential hazards associated with rigging equipment and take appropriate safety precautions.

- Inspectors should wear appropriate personal protective equipment (PPE), such as hard hats, safety glasses, and gloves.

- Inspectors should be aware of the potential for dropped objects and take precautions to prevent injuries.

- Inspectors should not attempt to repair or modify rigging equipment without proper training and authorization.

- Inspectors should report any unsafe conditions or practices to the appropriate authorities.

Failure to properly inspect rigging equipment can have serious consequences, including equipment failure, injuries, or even death.

Commonly Asked Questions

What is a competent person?

A competent person is someone who has the knowledge, skills, and experience to identify and assess the condition of rigging equipment and to make decisions about its continued use.

What are the responsibilities of a competent person?

The responsibilities of a competent person include inspecting rigging equipment, identifying and assessing defects, and making decisions about the continued use of the equipment.

How often should rigging equipment be inspected?

The frequency of inspections will vary depending on the type of equipment being inspected, but it should generally be inspected at least once a year.