Each platform must be fully planked to ensure its stability and safety. Proper planking provides numerous benefits, including enhanced structural integrity, improved load-bearing capacity, and increased resistance to wear and tear. By adhering to best practices for planking materials and techniques, you can significantly extend the lifespan of your platforms and minimize the risk of accidents.

This comprehensive guide will delve into the essential aspects of platform planking, providing you with the knowledge and skills necessary to ensure the safety and longevity of your platforms.

Platform Planking Requirements

Proper planking is crucial for ensuring the stability and safety of platforms. It involves installing planks or boards on the platform’s frame to create a solid and level surface.

Benefits of proper planking include:

- Improved platform stability by distributing weight evenly across the frame.

- Increased safety by reducing the risk of tripping or falling through gaps in the platform.

- Enhanced durability by protecting the platform frame from wear and tear.

Example of Planking Improvement

For instance, a properly planked platform used in construction can withstand the weight of workers and materials, ensuring a stable work surface. This reduces the risk of accidents and improves overall safety on the construction site.

Planking Materials and Methods

Planking is the process of laying down planks of wood or other materials to create a flat surface, typically for flooring or decking. The choice of planking material depends on several factors, including the intended use, budget, and desired aesthetic.

Planking Materials

| Material | Pros | Cons ||—|—|—|| Wood | Durable, natural-looking, easy to work with | Can be expensive, requires regular maintenance || Composite | Low-maintenance, moisture-resistant, durable | Can be more expensive than wood, may fade over time || Vinyl | Waterproof, easy to clean, affordable | Can be slippery, may not be as durable as wood or composite || Metal | Durable, fire-resistant, low-maintenance | Can be noisy, may rust |

Planking Process

The process of planking a platform involves several steps:1.

-

-*Prepare the substructure

This involves creating a level and stable base for the planks. For a wooden platform, this may involve laying down joists or sleepers.

- 2.

- 3.

- 4.

-*Install the planks

The planks are then laid down perpendicular to the joists or sleepers. They can be attached using nails, screws, or glue.

-*Secure the planks

The planks should be securely fastened to the substructure to prevent them from moving or shifting.

-*Finish the surface

The planked surface can be finished with a variety of materials, such as paint, stain, or sealant, to protect it from the elements and enhance its appearance.

Inspection and Maintenance

Regular platform inspections are essential for ensuring the safety and longevity of planked platforms. Inspections should be conducted at regular intervals, as determined by the platform’s usage and environment.

During inspections, the planking should be carefully examined for any signs of damage or deterioration, such as cracks, splinters, or rot. Loose or damaged planks should be replaced immediately to prevent accidents.

Inspection Checklist

The following checklist provides a comprehensive guide for inspecting planked platforms:

- Check for loose or damaged planks.

- Examine the planking for cracks, splinters, or rot.

- Inspect the supports and joists for any signs of damage.

- Look for any tripping hazards, such as uneven or warped planks.

- Check the hardware for any signs of rust or corrosion.

Case Studies and Examples

To illustrate the effectiveness of proper platform planking, we present several case studies and examples of successful projects.

These examples showcase the challenges encountered and lessons learned during the implementation process, providing valuable insights into best practices and the transformative impact of proper planking.

Successful Implementation of Platform Planking

One notable project involved the renovation of an aging industrial facility. The existing platform surfaces were uneven, slippery, and posed significant safety hazards to workers. The facility opted for a comprehensive planking solution that included the installation of durable, slip-resistant planking materials and the implementation of a rigorous inspection and maintenance program.

The results were remarkable. The new planking provided a safe and stable work environment, reducing the risk of accidents and improving worker productivity. The facility also experienced significant cost savings due to the reduced need for repairs and maintenance.

Overcoming Challenges in Platform Planking

Another case study involved a large-scale construction project where the planking requirements were particularly demanding. The project faced challenges such as uneven terrain, heavy equipment, and extreme weather conditions. The project team collaborated closely with planking experts to develop innovative solutions, including the use of specialized materials and advanced installation techniques.

Through careful planning and meticulous execution, the team successfully overcame these challenges and delivered a project with high-quality planking that met all safety and performance standards.

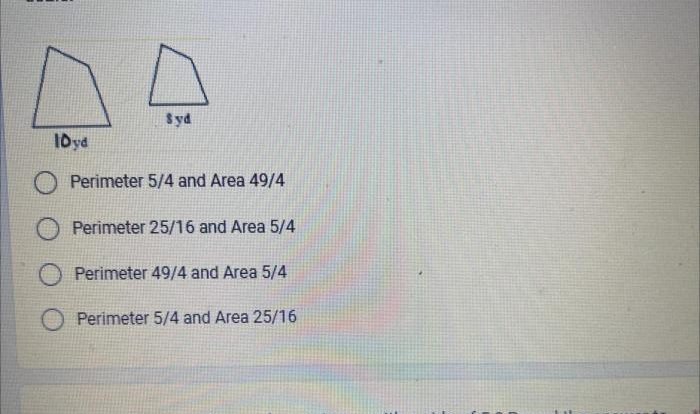

Visual Impact of Platform Planking, Each platform must be fully planked

Before-and-after photos of platform planking projects provide a compelling visual representation of the transformative impact of proper planking. These images clearly demonstrate the improvement in surface condition, safety, and overall aesthetics.

In one example, a warehouse underwent a complete platform planking renovation. The original platform was deteriorated and hazardous, with uneven surfaces and exposed nails. After the renovation, the platform was transformed with new, durable planking that provided a safe and efficient work environment.

FAQ Insights: Each Platform Must Be Fully Planked

Why is it important to fully plank each platform?

Fully planking each platform is crucial for ensuring its stability and safety. Proper planking distributes weight evenly, prevents sagging, and enhances the platform’s resistance to impact and wear.

What are the benefits of proper planking?

Proper planking provides numerous benefits, including increased structural integrity, improved load-bearing capacity, enhanced resistance to wear and tear, and reduced risk of accidents.

How often should platforms be inspected?

Platforms should be inspected regularly, ideally every six months or annually, to identify any damage or deterioration. Regular inspections help ensure that platforms remain safe and functional.